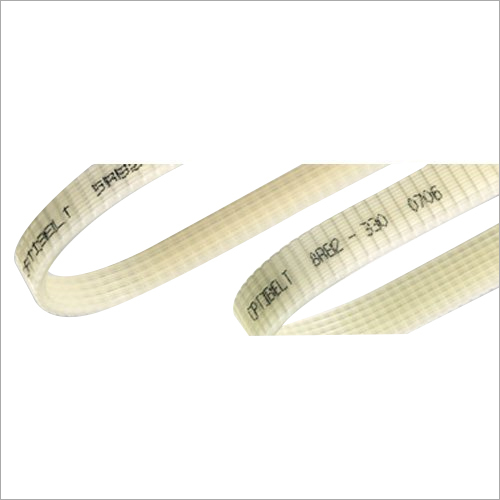

Optibelt Omega Ribbed Belts

Price 350 INR/ Meter

Optibelt Omega Ribbed Belts Specification

- Thickness

- Varies (standard sizes available)

- Surface Finish

- Precision machined ribbed surface

- Belt Type

- Omega Ribbed

- Features

- Low noise, maintenance free, high flexibility

- Power Source

- Driven by pulleys

- Material

- Synthetic rubber compound with high-strength tension cords

- Type

- Ribbed Belt (Poly V-Belt)

- Structure

- Multiple longitudinal ribs

- Belt Conveyor

- Compatible

- Roller Conveyor

- Not compatible

- Resistant Feature

- Highly resistant to abrasion, oil, and temperature

- Load Capacity

- High load transmission capability

- Power

- Suitable for high power transmission

- Speed

- Capable of high-speed operation

- Usage & Applications

- For industrial machinery, drive systems, compressors, pumps, and ventilation fans

Optibelt Omega Ribbed Belts Trade Information

- Minimum Order Quantity

- 10 Pieces

- Supply Ability

- 200 Pieces Per Day

- Delivery Time

- 3 Days

- Main Domestic Market

- All India

About Optibelt Omega Ribbed Belts

Usage, Advantage & Application Directions

Optibelt Omega Ribbed Belts are regularly used by industrial manufacturers and engineers seeking a reliable, high performance solution. The competitive advantages include exceptional load capacity, high flexibility, and minimal noise. To ensure optimum results, belts should be installed according to DIN/ISO direction and stored in cool, dry places away from direct sunlight. These belts are ideal for compressors, pumps, ventilators, and machinery requiring elite power, even with small pulley diameters.

Domestic Market & Packaging Details

Optibelt Omega Ribbed Belts find a strong domestic market across India's major industrial hubs. Packaging is meticulously done for secure drop-off, ensuring belts are dispatched and shipped in precision-protected cartons designed for safe transport. With robust supply ability, the belts are readily available for distributor, supplier, and trader requirements, supporting both standard and custom-demand orders in India, guaranteeing prompt shipping and reliable product quality with every dispatch.

FAQ's of Optibelt Omega Ribbed Belts:

Q: How do Optibelt Omega Ribbed Belts provide savings for industrial users?

A: Optibelt Omega Ribbed Belts offer significant savings by combining superb durability, low maintenance requirements, and high resistance to wear and temperature, resulting in reduced replacement frequency and minimized downtime costs.Q: What are the available rib configurations and profiles for these belts?

A: The belts are offered in multiple rib configurations, including PJ, PK, PL, and PM profiles, catering to various industrial machinery specifications and ensuring optimal performance for different applications.Q: Where should Optibelt Omega Ribbed Belts be stored to maintain quality?

A: To preserve belt quality, they should be stored in cool, dry conditions away from direct sunlight, which helps maintain flexibility and antistatic properties for long-term performance reliability.Q: When should businesses use Omega Ribbed Belts in their drive systems?

A: Omega Ribbed Belts are suited for use in machinery, compressors, pumps, and fans when high load transmission, elite temperature resistance, and quiet, maintenance-free operation are required.Q: What process ensures the belts meet international quality standards?

A: Optibelt Omega Ribbed Belts conform to rigorous DIN/ISO specifications and ISO 1813 antistatic standards, with precision-machined rib surfaces, ensuring each belt delivers superb operational reliability.Q: How does the belt's high elasticity benefit applications with small pulley diameters?

A: High elasticity allows these sought-after ribbed belts to operate efficiently on small pulley diameters, enabling space-saving installations and enhancing versatility in compact machinery setups.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Ribbed Belts Category

Optibelt Elastic Ribbed Belts

Price 300 INR / Meter

Minimum Order Quantity : 10 Pieces

Structure : Other, Ribbed (multiV) with elastic core

Type : Other, Elastic Ribbed Belt

Material : Highstrength synthetic rubber with tensile cords (polyamide/polyester/elastomer)

Roller Conveyor : Other, Compatible for drive systems

Optibelt Conveyor Power Ribbed Belts

Price 350 INR / Meter

Minimum Order Quantity : 5 Pieces

Structure : Other, Multiribbed with highflexibility

Type : Other, Ribbed belt, PolyV profile

Material : Highquality rubber with polyester/aramid tension members

Roller Conveyor : Other, No

Optibelt Ribbed Belts

Price 650 INR / Meter

Minimum Order Quantity : 200

Structure : Belt

Type : Belt Conveyor

Material : PU

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry