Table Top Chain Sprocket

Price 100 INR/ Meter

Table Top Chain Sprocket Specification

- Features

- High wear resistance, durable construction, smooth operation

- Thickness

- Range: 10 mm to 35 mm (customizable)

- Belt Type

- Table Top Chain

- Surface Finish

- Polished / Zinc-Plated / Painted (as specified)

- Power Source

- Mechanical Drive

- Material

- Stainless Steel / Mild Steel / Plastic (as per requirement)

- Type

- Table Top Chain Sprocket

- Structure

- Machined with precision bores and keyways

- Belt Conveyor

- Suitable for Table Top Chain Conveyors

- Roller Conveyor

- Not Compatible

- Vertical Conveyor

- Compatible

- Resistant Feature

- Corrosion Resistant & Abrasion Resistant

- Load Capacity

- High (up to 1500 kg depending on material and size)

- Voltage

- Not Required for Mechanical Sprocket

- Speed

- Suitable for chain speeds up to 70 m/min

- Usage & Applications

- Used in food processing, packaging, beverage, automotive, and material handling industries

Table Top Chain Sprocket Trade Information

- Minimum Order Quantity

- 200 Meter

- Supply Ability

- 200 Per Day

- Delivery Time

- 3 Days

About Table Top Chain Sprocket

Keeping in track the varied necessity of patrons, we are supplying a wide ambit of Table Top Chain Sprockets. These are made with a highly specialized tools and components to deliver a premium quality. These sprockets are easily operated under thermal as well as atmospheric conditions. Table Top Chain Sprockets are suitable for both long and short distance of power transmissions. These series are useful to transmit power from one to another tool with a great ease.

Customizable for a Perfect Fit

Each table top chain sprocket is engineered with flexibility in mind, allowing customers to specify the number of teeth, bore type, hub style, and pitch diameter according to the chain and conveyor design used in their facility. This ensures optimal compatibility and seamless integration into existing systems, enhancing productivity and operational reliability.

Built for Durability and Versatility

Available in stainless steel, mild steel, or high-quality plastics, these sprockets are designed to withstand harsh industrial environments. Their corrosion and abrasion-resistant properties make them ideal for industries where hygiene and longevity are paramount, such as food processing, packaging, and pharmaceuticals. The high load capacity and smooth operation further boost their appeal across multiple sectors.

FAQs of Table Top Chain Sprocket:

Q: How do I select the correct table top chain sprocket for my conveyor system?

A: Selecting the right sprocket involves identifying your chain pitch (1.5 inch, 2 inch, or custom), determining the required number of teeth and pitch diameter, and matching bore size, hub type, and mounting method to your conveyor design. Contact us with your specifications for tailored assistance.Q: What makes these sprockets suitable for food, beverage, and pharmaceutical industries?

A: These sprockets are manufactured from materials like stainless steel and durable plastics, providing high corrosion and abrasion resistance suitable for sensitive environments. They are machined with precision for hygienic, reliable operation and easy maintenance, meeting stringent industry standards.Q: Where can these sprockets be used in industrial applications?

A: They are extensively employed in food processing, beverage bottling, packaging, pharmaceuticals, and automotive assembly linesanywhere table top chain conveyors are used for material handling or product movement.Q: What is the process for ordering a custom sprocket?

A: To order, specify the chain pitch, number of teeth, bore size, hub type, mounting method, material, surface finish, thickness, and color preferences. Our engineering team will assist in confirming suitability for your application before proceeding to production.Q: What benefits do customizable table top chain sprockets offer?

A: Custom sprockets ensure precise fit, optimum chain engagement, and efficient conveyor operation. Their robust construction and adaptability to various mounting methods extend service life while minimizing downtime, improving overall productivity.Q: Can these sprockets be used on vertical conveyors?

A: Yes, these sprockets are engineered for compatibility with vertical as well as horizontal table top chain conveyors, allowing for flexible use in different material flow configurations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Modular Conveyor Chains and Component Category

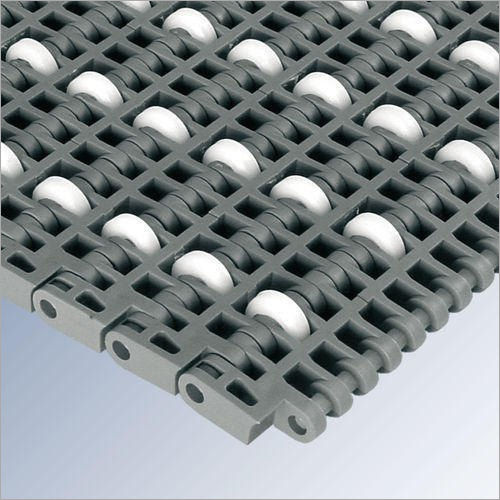

Plastic Chain Conveyor Belt

Price 350 INR / Meter

Minimum Order Quantity : 200

Type : Other, Plastic Chain Conveyor Belt

Usage & Applications : Food Processing, Packaging, Bottling, Pharmaceuticals, Material Handling

Power Source : Electric

Surface Finish : Smooth / Matt

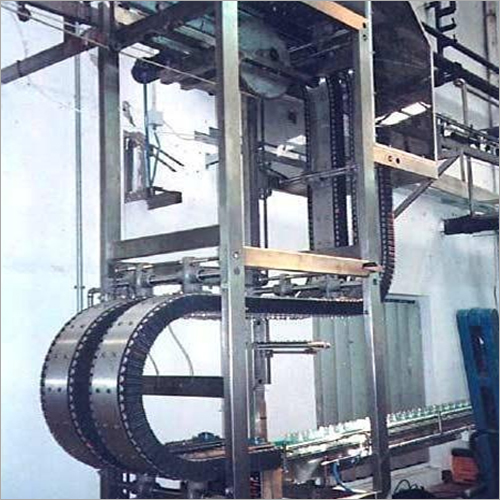

Multiflex Chain and Case Conveyor Chain Sprocket

Price 978 INR / Meter

Minimum Order Quantity : 200

Type : Other, Case Conveyor Chain Sprocket

Usage & Applications : Carton, Case and Bottle Conveying; Food, Beverage, Packaging Industries

Power Source : Manual/Driven by Conveyor Motor

Surface Finish : Smooth, Precision Machined

Plate Top Gripper Chain

Price 180 INR / Meter

Minimum Order Quantity : 200

Type : Other, Top Gripper Chain

Usage & Applications : Inclined or Vertical Product Transfer, Packaging, Bottling, Food & Beverage Industry

Power Source : Mechanical

Surface Finish : Smooth Polished

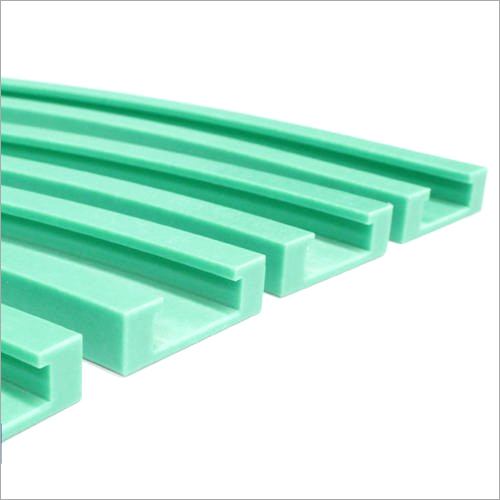

Tab Curves Conveyor Component

Price 1100 INR / Meter

Minimum Order Quantity : 200

Type : Other, Tab Curves Conveyor Component

Usage & Applications : Material Handling, Food Processing, Packaging Lines

Power Source : Manual/Integrated with Conveyor Drive

Surface Finish : Smooth, Glossy Finish

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry