Plastic Table Top Chain With Rubber Top

Price 1600 INR/ Meter

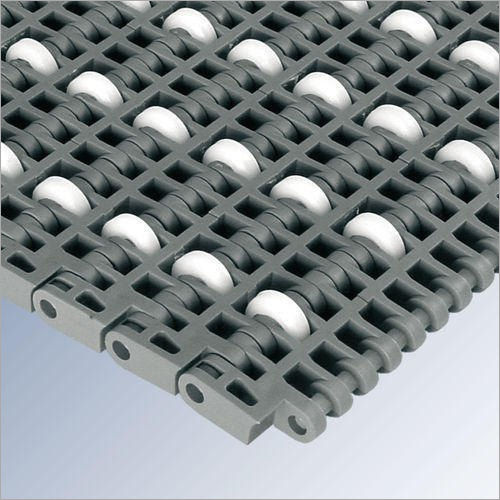

Plastic Table Top Chain With Rubber Top Specification

- Belt Type

- Flat Top with Rubber Surface

- Power Source

- Gravity / Mechanically Driven

- Features

- Non-slip Rubber Top Surface, High Load Bearing Capacity, Low Friction, Easy to Clean, Maintenance Free

- Thickness

- Standard: 5-10 mm

- Surface Finish

- Smooth with Anti-Slip Rubber Top

- Material

- Engineering Plastic with Rubber Inserts

- Type

- Modular Plastic Table Top Chain with Rubber Top

- Structure

- Single Chain

- Belt Conveyor

- Compatible

- Roller Conveyor

- Not Compatible

- Vertical Conveyor

- Not Compatible

- Pneumatic Conveyor

- Not Compatible

- Resistant Feature

- Corrosion Resistant, Chemical Resistant, Wear Resistant

- Load Capacity

- Up to 150 kg/m

- Voltage

- Not Required (Non-Electric Component)

- Speed

- Up to 80 m/min

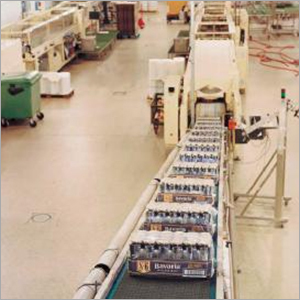

- Usage & Applications

- Food Processing, Beverage Bottling, Packaging, Pharmaceutical and Automated Assembly Lines

- Rubber Insert Material

- Nitrile Rubber or EPDM

- Maintenance

- Minimal, Lubrication Not Required

- Chain Width

- 82.5 mm, 101.6 mm, 114.3 mm (Customizable)

- Noise Level

- Low (Below 70 dB at normal operation)

- Weight Per Meter

- 1.5-2.5 kg/m (Depending on Width)

- Standard Length Per Chain

- 3.048 m (10 feet)

- Link Material

- Acetal, Polypropylene, Polyethylene (as per requirement)

- Operating Temperature Range

- -10°C to +80°C

- Color

- White / Grey with Black Rubber Inserts

- Side Flexing

- Available (Optional)

- Chain Pitch

- 38.1 mm (Standard)

- Installation

- Modular & Tool-Free Assembly

- Pin Material

- Stainless Steel / Plastic

Plastic Table Top Chain With Rubber Top Trade Information

- Minimum Order Quantity

- 200 Meter

- Supply Ability

- 200 Per Day

- Delivery Time

- 3 Days

About Plastic Table Top Chain With Rubber Top

Highlighting Premium Features and Superior Materials

The Plastic Table Top Chain With Rubber Top stands out with its exceptional material composition and premium-grade rubber inserts. Engineered from acetal, polypropylene, or polyethylene, paired with stainless steel or resilient plastic pins, it's designed to endure harsh industrial environments. The chain's smooth, anti-slip surface ensures operational safety and supports substantial loads up to 150 kg/m. Its easy-to-clean, low-friction profile, combined with tool-free modular installation, offers users a maintenance-free, high-performing solution ideal for fast-paced automation.

Secure Packaging and Competitive Sale Price Details

This product is delivered through secure shipping methods to assure damage-free receipt. We offer clear outlay details, ensuring financial transparency for every purchase. The FOB port for export is located in India, facilitating timely global dispatch. Sample units are available on request, enabling you to evaluate its unmatchable performance before bulk procurement. Rely on us as your distributor and supplier for both single and large-scale orders, and secure the best sale price for maintenance-free, invincible conveyor solutions.

FAQ's of Plastic Table Top Chain With Rubber Top:

Q: How is the Plastic Table Top Chain With Rubber Top installed?

A: Installation is simple and tool-free due to its modular assembly design, allowing rapid setup and easy replacement or extension according to your system's requirements.Q: What makes this chain suitable for high-load industrial applications?

A: The chain's robust engineering using premium acetal or polypropylene materials and reinforced rubber inserts ensures it can handle load capacities up to 150 kg/m and resist wear and corrosion in demanding environments.Q: When should I choose side flexing or standard configuration?

A: Opt for side flexing when your conveyor path requires curves or directional changes. For straight-line applications, the standard single-chain configuration suffices.Q: Where is this chain most effectively used?

A: This chain excels in food processing, beverage bottling, packaging, and pharmaceutical assembly lines due to its non-slip surface, chemical resistance, and ease of cleaning.Q: What are the benefits of choosing this unmatchable modular chain over traditional belts?

A: It offers lower noise operation, easier maintenance, superior load capacity, and a non-slip surface. Unlike traditional belts, no lubrication is required and cleaning is effortless.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Modular Conveyor Chains and Component Category

Plastic Chain Conveyor Belt

Price 350 INR / Meter

Minimum Order Quantity : 200

Features : Low Friction, Easy to Clean, NonCorrosive, High Durability

Power Source : Electric

Type : Other, Plastic Chain Conveyor Belt

Load Capacity : Up to 200 kg/meter

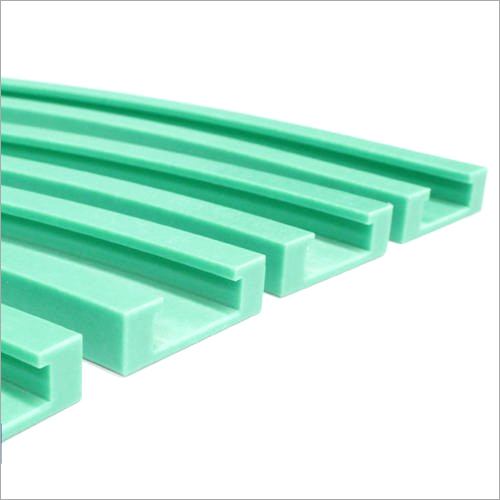

Frame Support Conveyor Component

Price 850 INR / Meter

Minimum Order Quantity : 200

Features : High Stability, Easy Installation, Robust Design

Power Source : Electric

Type : Other, Frame Support Conveyor Component

Load Capacity : Up to 500 kg

Rexnord MCC Mattop Modular Conveyor Belt

Price 300 INR / Meter

Minimum Order Quantity : 200

Features : Easy to Clean, High Strength, Low Maintenance, Modular Design

Power Source : Mechanically Driven

Type : Other, Modular Mattop Conveyor Belt

Load Capacity : Up to 2000 kg or customized

Tab Curves Conveyor Component

Price 1100 INR / Meter

Minimum Order Quantity : 200

Features : Precise Curving, High Durability, Low Friction

Power Source : Manual/Integrated with Conveyor Drive

Type : Other, Tab Curves Conveyor Component

Load Capacity : Up to 100 kg/m

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry