Plastic Table Top LBP Conveyor Chain

Price 500 INR/ Meter

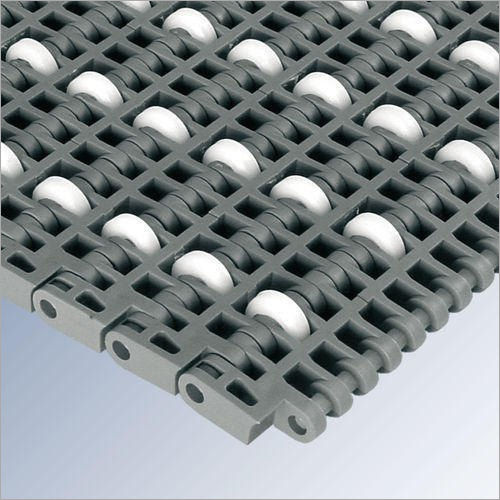

Plastic Table Top LBP Conveyor Chain Specification

- Power Source

- Manual/Integrated with conveyor motor drive

- Features

- Low back pressure, high strength, anti-jamming, modular design, easy installation, maintenance free

- Surface Finish

- Smooth, low-friction, glossy finish

- Thickness

- Standard: 8 mm 12 mm depending on model

- Belt Type

- Table Top Modular Chain

- Material

- High-grade thermoplastic/engineering plastic (e.g., Acetal, POM)

- Type

- LBP (Low Back Pressure) Plastic Table Top Chain

- Structure

- Flat modular chain with link interlocking

- Belt Conveyor

- Compatible with flat belt and modular system

- Resistant Feature

- Corrosion resistant, chemical resistant, wear resistant

- Load Capacity

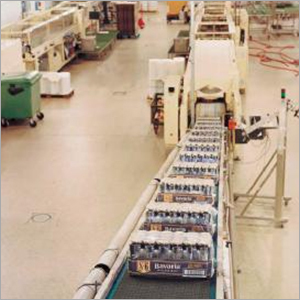

- High; suitable for heavy loads in bottling, packaging, and material handling

- Power

- Manual/Mechanical operation

- Speed

- Up to 60 meters per minute

- Usage & Applications

- Automated material handling, beverage bottling lines, food processing, packaging, pharmaceuticals

- Lubrication

- No lubrication required

- Chain Color

- White / Grey / Customized

- FDA Approval

- Yes

- Friction Coefficient

- Low

- Maintenance Requirement

- Low

- Link Width

- 82.5 mm

- Assembly Style

- Snap-On, Easy-to-Assemble

- Pitch Size

- 38.1 mm

- Heat Resistance

- High

- Working Temperature Range

- -40°C to +90°C

Plastic Table Top LBP Conveyor Chain Trade Information

- Minimum Order Quantity

- 200 Meter

- Supply Ability

- 200 Per Day

- Delivery Time

- 3 Days

About Plastic Table Top LBP Conveyor Chain

We are successfully dealing a broad series of Plastic Table Top LBP Conveyor Chain. It is featured for its smooth performance as well as require a minimum maintenance. It is used with the support of connecting pin. Plastic Table Top LBP Conveyor Chain is availed in many sizes to meet the specific needs of respected consumers. It reduce the scratches and line pressure effectively. It is also useful for glass bottles, crates and many other industrial applications.

Exceptional Durability and Resistance

Manufactured from superior thermoplastics, the chain boasts excellent corrosion, chemical, and wear resistance, making it ideal for demanding industrial environments. Its robust interlocking flat modular structure enhances longevity and overall performance, even under heavy load conditions.

Effortless Assembly and Low Maintenance

The Plastic Table Top LBP Conveyor Chain features a user-friendly snap-on design, simplifying installation and replacement. Maintenance demands are minimal, with no lubrication required and anti-jamming properties ensuring unstoppable operation. The modular structure allows for easy customization and system compatibility.

Ideal for Diverse Material Handling Applications

With its high load capacity, low back pressure design, and smooth surface finish, this conveyor chain efficiently handles packaging, beverage bottling, food processing, and pharmaceutical tasks. FDA approval and resistance to extreme temperatures further support its suitability in stringent industrial and hygienic settings.

FAQs of Plastic Table Top LBP Conveyor Chain:

Q: How does the snap-on assembly design benefit installation and maintenance?

A: The snap-on assembly allows for quick and easy installation or removal of the chain links without specialized tools or lengthy downtime. This modular approach greatly simplifies maintenance and makes system customization straightforward, saving both time and labor costs.Q: What applications are best suited for the Plastic Table Top LBP Conveyor Chain?

A: This conveyor chain excels in heavy-load material handling environments, such as beverage bottling lines, food processing facilities, packaging plants, and pharmaceutical environments. Its high strength, low friction, and hygiene-focused design are specifically tailored for rigorous industrial processes.Q: When should this conveyor chain be used over a traditional metal chain?

A: Choose this plastic chain when low back pressure, resistance to corrosion and chemicals, and a requirement for minimal maintenance are priorities. It is particularly beneficial where high sanitation standards (e.g., FDA compliance) and non-lubricated, low-noise operation are preferred.Q: Where can the chain be installed, and what conveyor systems is it compatible with?

A: The chain fits both flat belt and modular conveyor systems. It can be implemented in a variety of locations, from industrial production lines to packaging, processing, and logistics environments, wherever reliable and hygienic material handling is needed.Q: What is the working temperature range, and how does the chain handle extreme conditions?

A: The chain operates effectively in temperatures ranging from -40C to +90C, making it highly suitable for both cold storage processing and high-heat environments without compromising performance, wear resistance, or structural integrity.Q: How does the low back pressure (LBP) feature enhance efficiency?

A: The LBP design minimizes friction and product accumulation forces, ensuring smoother material flow and less risk of jamming or product damage during conveyancecrucial in fast-moving automated production lines.Q: What maintenance is required and are there lubrication needs?

A: Maintenance requirements are minimal due to the high-quality plastic materials and snap-on modular design. The chain does not require lubrication, reducing the risk of contamination and simplifying upkeep, especially in food-grade and clean environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Modular Conveyor Chains and Component Category

Plastic Chain Conveyor Belt

Price 350 INR / Meter

Minimum Order Quantity : 200

Usage & Applications : Food Processing, Packaging, Bottling, Pharmaceuticals, Material Handling

Type : Other, Plastic Chain Conveyor Belt

Belt Type : Modular Plastic Chain

Structure : Other, Modular Plastic Chain

Frame Support Conveyor Component

Price 850 INR / Meter

Minimum Order Quantity : 200

Usage & Applications : Industrial Conveyor Systems, Assembly Lines, and Material Handling

Type : Other, Frame Support Conveyor Component

Belt Type : Customizable (PVC/Rubber/PU)

Structure : Other, Modular Frame, Welded Construction

Rexnord MCC Mattop Modular Conveyor Belt

Price 300 INR / Meter

Minimum Order Quantity : 200

Usage & Applications : Automotive, Food & Beverage, Packaging, Bottling, Material Handling

Type : Other, Modular Mattop Conveyor Belt

Belt Type : Mattop Modular

Structure : Other, Modular Plastic Chain

Bevel Curves Conveyor Component

Price 985 INR / Meter

Minimum Order Quantity : 200

Usage & Applications : Material handling, packaging, assembly lines, warehouses

Type : Other, Bevel Curves Conveyor Component

Belt Type : PU or PVC belt

Structure : Other, Curved modular frame with supports

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry