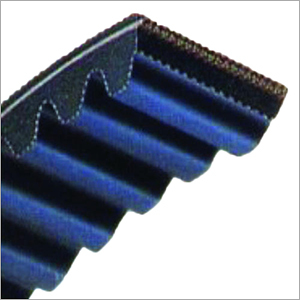

Continental Synchro Transmission Belt

Price 655 INR/ Meter

Continental Synchro Transmission Belt Specification

- Product Type

- Synchro Transmission Belt

- Material

- High-strength synthetic rubber with polyester tension members

- Capacity

- Designed for high power transmission applications

- Protection

- Abrasion and oil resistant

- Application

- Industrial machinery, conveyors, power transmission systems

- Size

- Standard and custom sizes available (per application)

- Weight

- Varies based on belt size

- Dimension (L*W*H)

- Dimension depends on belt specification

- Color

- Black

- Backing Material

- Fabric-backed for noise reduction

- Belt Type

- Timing/Synchronous Belt

- Construction

- Molded teeth and flexible cord reinforcement

- Temperature Range

- -30C to +85C

- Flex Rating

- Suitable for high flex cycles

- Static Conductivity

- Antistatic properties as per ISO standards

- Tooth Profile

- Synchronous tooth profile for efficient power transmission

- Compliance

- RoHS compliant

- Tensile Strength

- High tensile strength for heavy-duty operations

- Maintenance

- Low maintenance required

Continental Synchro Transmission Belt Trade Information

- Minimum Order Quantity

- 200 , , Meter

- Supply Ability

- 2000 Per Day

- Delivery Time

- 3 Days

About Continental Synchro Transmission Belt

We are actively engaged in rendering a broad variety of Continental Synchro Transmission Belt. It is mostly used in home appliances, camshaft drives and many other types of equipment tools. This belt delivers a high performance and utilized for a longer time. Continental Synchro Transmission Belt is easy to use without causing any issue of slippage. It aids to improve the tooth strength. It doesnt require any extra maintenance. It allows less installation and handle in a reliable manner.

Efficient and Quiet Power Transmission

Designed with a synchronous tooth profile and fabric-backed material, the Synchro Transmission Belt enables precise timing and reduced noise in demanding industrial environments. Its molded teeth enhance grip and durability, supporting smooth operation even in high flex cycle applications.

Built for Durability and Compliance

Constructed from high-strength synthetic rubber and polyester tension members, the Continental belt offers robust tensile strength and is engineered to resist abrasion and oil exposure. It complies fully with RoHS standards, ensuring safety and reliability while meeting the highest industrial requirements.

Custom Sizing and Versatile Applications

This transmission belt is available in both standard and bespoke sizes, making it suitable for a variety of machinery, conveyor systems, and heavy-duty equipment. Its versatility and protective features make it a preferred choice for distributors and manufacturers across India.

FAQ's of Continental Synchro Transmission Belt:

Q: How does the synchronous tooth profile improve power transmission efficiency?

A: The synchronous tooth profile ensures accurate belt engagement with pulleys, minimizing slippage and optimizing power transfer, which leads to better performance and energy efficiency in industrial machinery.Q: What benefit does the fabric-backed design provide during operation?

A: The fabric backing significantly reduces operational noise, providing quieter machinery environments and enhancing comfort and communication for operators working near the equipment.Q: When should I consider custom sizing for the Continental Synchro Transmission Belt?

A: Custom sizes are recommended when standard belts do not fit the specific requirements of your application, such as unique machinery configurations or specialized conveyor systems. Contact your supplier or distributor for tailored solutions.Q: Where is this transmission belt commonly used in industry?

A: It is widely employed in industrial machinery, conveyor systems, high-power transmission setups, and other heavy-duty equipment, delivering reliable and consistent performance for both manufacturing and export operations throughout India.Q: What maintenance process should be followed to ensure longevity of the belt?

A: Thanks to its low-maintenance design, periodic inspection for wear, appropriate tensioning, and keeping the belt clean from debris are generally sufficient to maximize operational lifespan and efficiency.Q: How does compliance with ISO antistatic standards benefit my applications?

A: ISO-compliant antistatic properties reduce the risk of electrostatic discharge, helping maintain equipment safety and performance, especially in environments sensitive to static build-up.Q: What makes this belt suitable for high flex cycles and heavy-duty operations?

A: Its flexible cord reinforcement and high-strength synthetic rubber construction deliver superior tensile strength and flexibility, allowing it to withstand frequent flexing and heavy loads without compromising performance or durability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Power Transmission Belts Category

Continental Synchrochain Transmission Belt

Price 670 INR / Meter

Minimum Order Quantity : 200

Material : Highstrength polyurethane with steel tension members

Weight : Depends on size (approx. 0.1 2.5 kg/m)

Output Power : Up to 70 kW (depending on size and application)

Size : Customizable (standard widths and lengths available)

SWR Europe Variable Speed Belt

Price 650 INR / Meter

Minimum Order Quantity : 200

Material : Highgrade rubber with polyester cords

Weight : Variable as per dimensions (typical: 250g 2kg)

Output Power : Up to 30 kW (varies by size)

Size : Available in multiple widths and lengths (customizable as per requirement)

Conti Synchro Force Xtreme And Supreme Transmission Belt

Price 500 INR / Meter

Minimum Order Quantity : 200

Material : PU

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry