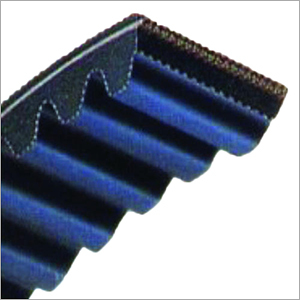

Continental Synchrochain Transmission Belt

Price 670 INR/ Meter

Continental Synchrochain Transmission Belt Specification

- Product Type

- Synchrochain Transmission Belt

- Material

- High-strength polyurethane with steel tension members

- Capacity

- Designed for high-torque transmittion in industrial applications

- Output Power

- Up to 70 kW (depending on size and application)

- Protection

- Resistant to oil, grease, and water

- Output Type

- Mechanical power transmission

- Application

- Industrial drives, conveyors, robotics, heavy-duty transmission

- Size

- Customizable (standard widths and lengths available)

- Weight

- Depends on size (approx. 0.1 2.5 kg/m)

- Dimension (L*W*H)

- Varies by model (e.g., L=500mm-4500mm, W=12mm-100mm)

- Color

- Grey/Black

- Noise Level

- Low noise operation

- Antistatic Properties

- Available as antistatic on request

- Standards Compliance

- ISO 13050, DIN 7721

- Maintenance

- Virtually maintenance-free

- Tooth Profile

- Synchrochain Carbon CTD / STD / AT10 profiles

- Tensile Member

- Special high-strength steel cords

- Surface Finish

- Abrasion resistant

- Flexibility

- Designed for minimal elongation and high shock load tolerance

- Elongation

- < 0.2% at recommended loads

- Belt Pitch

- Typically 8 mm (other pitches available on request)

- Temperature Resistance

- -30°C to +100°C

Continental Synchrochain Transmission Belt Trade Information

- Minimum Order Quantity

- 200 Meter

- Supply Ability

- 2000 Per Day

- Delivery Time

- 3 Days

About Continental Synchrochain Transmission Belt

We are able to supply a wide series of Continental Synchrochain Transmission Belt. It is basically require for transmitting a large power outputs. This belt is known for its high torque and speed level. Apart from this, provided belt is a great alternatives of a chain drives. Continental Synchrochain Transmission Belt is used in textile machinery, business equipment and machinery components. It ensures a prolonged life and extreme power capacity. It can be configured as per the needs of consumers.

Optimized for Industrial Performance

This transmission belt is specifically designed for high-torque environments such as industrial drives, conveyors, and robotics. Its high-strength steel cords and polyurethane structure ensure minimal elongation and high shock load tolerance, contributing to consistent mechanical power output up to 70 kW.

Superior Material & Versatile Profiles

Available in Synchrochain Carbon CTD, STD, and AT10 tooth profiles, the belt offers flexibility and abrasion resistance for extended operating life. Customizable in pitch, width, and length, it adapts easily to diverse requirements across industries.

Reliable in Challenging Conditions

Operating smoothly from -30C to +100C and resisting oil, grease, and water, the belt functions dependably in demanding industrial settings. Its low noise and virtually maintenance-free design translates to less downtime and greater productivity.

FAQ's of Continental Synchrochain Transmission Belt:

Q: How should I select the appropriate tooth profile for my application?

A: The correct tooth profile-Synchrochain Carbon CTD, STD, or AT10-depends on your transmission requirements, desired torque, and compatibility with existing pulleys. Consulting with a Continental distributor or supplier will help you determine the best fit based on your machinery's specifications.Q: What are the main benefits of the abrasion-resistant surface finish?

A: The abrasion-resistant finish prolongs the belt's operational life by reducing wear from continuous contact with pulleys and gears. This ensures durable performance and minimizes the need for frequent replacement, ideal for intensive industrial processes.Q: When is it necessary to request antistatic properties for the belt?

A: Antistatic features should be considered for environments prone to static build-up, such as those handling sensitive electronics or powders. These properties are available on request to enhance safety and prevent static discharge during operation.Q: Where can the Continental Synchrochain Transmission Belt be installed?

A: The belt is suitable for a range of industrial machinery, including heavy-duty conveyors, robotics, and transmission drives. Its adaptability in size and pitch allows installation in diverse mechanical setups across manufacturing, automation, and processing plants in India.Q: What is the required maintenance for the Synchrochain belt?

A: Routine inspection is advisable, but the belt is designed to be virtually maintenance-free. Its materials and construction minimize elongation and wear, reducing the frequency of adjustments or replacements under recommended operating conditions.Q: How does the belt tolerate shock loads and high torque?

A: Thanks to its special high-strength steel cords and high-tensile polyurethane, the belt accommodates significant shock loads and transmits high torque reliably while maintaining minimal elongation (<0.2%), ensuring stable mechanical power distribution.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Power Transmission Belts Category

SWR Europe Variable Speed Belt

Price 650 INR / Meter

Minimum Order Quantity : 200

Material : Highgrade rubber with polyester cords

Weight : Variable as per dimensions (typical: 250g 2kg)

Dimension (L*W*H) : Customized (e.g., Width: 16mm38mm, Length: 500mm3000mm)

Color : Black with yellow or white labeling

Continental Synchro Transmission Belt

Price 655 INR / Meter

Minimum Order Quantity : 200

Material : Highstrength synthetic rubber with polyester tension members

Weight : Varies based on belt size

Dimension (L*W*H) : Dimension depends on belt specification

Color : Black

Conti Synchro Force Xtreme And Supreme Transmission Belt

Price 500 INR / Meter

Minimum Order Quantity : 200

Material : PU

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry