Contitech SilentSync Belt

Price 150 INR/ Meter

Contitech SilentSync Belt Specification

- Thickness

- Varies by Belt Width and Pitch

- Features

- Low Noise Operation, Precise Positioning, Maintenance Free, High Strength

- Belt Type

- SilentSync Timing Belt (Synchronous Belt)

- Surface Finish

- Smooth or Fabric Top

- Power Source

- Driven by Mechanical Power Transmission

- Material

- Polyurethane with Steel Reinforcement

- Type

- Synchronous Timing Belt

- Structure

- Polyurethane Belt with Helical Tooth Profile

- Belt Conveyor

- Suitable for Belt Drives

- Roller Conveyor

- Not Suitable

- Vertical Conveyor

- Not Suitable for Vertical Conveying

- Pneumatic Conveyor

- Not Applicable for Pneumatic Conveying

- Resistant Feature

- Oil, Heat and Abrasion Resistant

- Load Capacity

- High Torque Capacity, Loading as per standard size selection

- Power

- Mechanical Transmission; Not Electrically Powered

- Speed

- Up to 40 m/s depending on size and application

- Usage & Applications

- Industrial Automation, Packaging, Material Handling, Textile Machinery, Printing, High-Speed Drives

Contitech SilentSync Belt Trade Information

- Minimum Order Quantity

- 200 Meter

- Supply Ability

- 200 Per Day

- Delivery Time

- 3 Days

About Contitech SilentSync Belt

With the support of dexterous experts, we bring forth a wide ambit of Contitech Silent Sync Belts. These are engineered in the modern infrastructure unit which is managed with the support of skilled experts who are masters in this field. Contitech Silent Sync Belts are designed to provides a smooth and continuous rolling tooth engagement. These belts ensure a less vibration and no noise. They are useful for machine tools, textile tools and many others.

Advanced Tooth Design for Superior Performance

The helical tooth geometry of the SilentSync Belt minimizes noise and vibration during operation, providing smoother and quieter performance compared to conventional timing belts. This design innovation enhances system efficiency, reduces wear, and extends equipment life, making it valuable for environments where precision and low noise are critical.

Industrial Grade Durability and Compliance

Constructed from polyurethane reinforced with steel or aramid cords, this timing belt delivers exceptional strength and load-carrying capacity. The SilentSync Belt meets international standards, including RoHS compliance and ISO 9563 (antistatic) and ISO 5296, ensuring safe, reliable use across industries. Its oil, heat, and abrasion resistance allow for longevity under demanding operating conditions.

Versatile Applications and Custom Solutions

Designed for use in industrial automation, packaging, material handling, textile machinery, and high-speed machinery, the SilentSync Belt is adaptable for various mechanical power transmissions. It is available in different pitches and can be ordered in custom lengths, ensuring compatibility with complex conveyor systems and specialized equipment across India and globally.

FAQ's of Contitech SilentSync Belt:

Q: How does the helical tooth geometry of the SilentSync Belt reduce vibration and noise?

A: The helical tooth profile creates a continuous, rolling engagement with the pulley, which disperses operational forces more evenly. This results in lower vibration and significantly quieter performance, making the belt suitable for noise-sensitive industrial environments.Q: What industries and applications is the SilentSync Timing Belt best suited for?

A: This belt is widely used in industrial automation, packaging, material handling, textile machinery, printing presses, and high-speed drives. Its precise positioning, low noise, and maintenance-free operation make it ideal for these demanding applications.Q: When should I consider a custom length SilentSync Belt?

A: Custom lengths are recommended when your machinery or conveyor setup requires a specific belt size not covered by standard options. Custom belts ensure perfect fit and optimal performance, especially in specialized equipment or complex system layouts.Q: Where can I source the Contitech SilentSync Belt in India?

A: You can purchase the SilentSync Belt through authorized distributors, exporters, manufacturers, suppliers, and traders across India. These sources ensure genuine products and technical support for your application.Q: What is the process for selecting the correct pitch and width for my application?

A: Selection typically involves evaluating your required load capacity, speed, and pulley dimensions. The belt is available in 8mm, 14mm, and 20mm pitches, with thickness varying by width and pitch. Technical guidance from suppliers will help ensure proper sizing and compatibility.Q: How does the belt's construction benefit high-torque and high-speed applications?

A: Reinforcement with high strength steel or aramid cords gives the belt a high torque capacity and resistance to elongation, while its polyurethane body withstands heat, oil, and abrasion. This robust construction supports speeds up to 40 m/s and heavy-duty drive requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Modular Conveyor Chains and Component Category

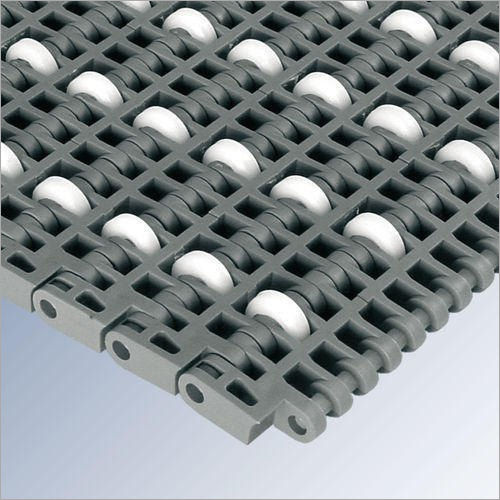

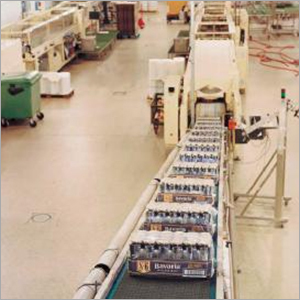

Plastic Chain Conveyor Belt

Price 350 INR / Meter

Minimum Order Quantity : 200

Features : Low Friction, Easy to Clean, NonCorrosive, High Durability

Usage & Applications : Food Processing, Packaging, Bottling, Pharmaceuticals, Material Handling

Belt Conveyor : Other, Yes

Belt Type : Modular Plastic Chain

Plastic Table Top Chain With Rubber Top

Price 1600 INR / Meter

Minimum Order Quantity : 200

Features : Nonslip Rubber Top Surface, High Load Bearing Capacity, Low Friction, Easy to Clean, Maintenance Free

Usage & Applications : Food Processing, Beverage Bottling, Packaging, Pharmaceutical and Automated Assembly Lines

Belt Conveyor : Other, Compatible

Belt Type : Flat Top with Rubber Surface

Rexnord MCC Mattop Modular Conveyor Belt

Price 300 INR / Meter

Minimum Order Quantity : 200

Features : Easy to Clean, High Strength, Low Maintenance, Modular Design

Usage & Applications : Automotive, Food & Beverage, Packaging, Bottling, Material Handling

Belt Conveyor : Other, Yes

Belt Type : Mattop Modular

Bevel Curves Conveyor Component

Price 985 INR / Meter

Minimum Order Quantity : 200

Features : High load capacity, smooth curve transition, easy maintenance

Usage & Applications : Material handling, packaging, assembly lines, warehouses

Belt Conveyor : Other, Compatible with modular belt systems

Belt Type : PU or PVC belt

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry