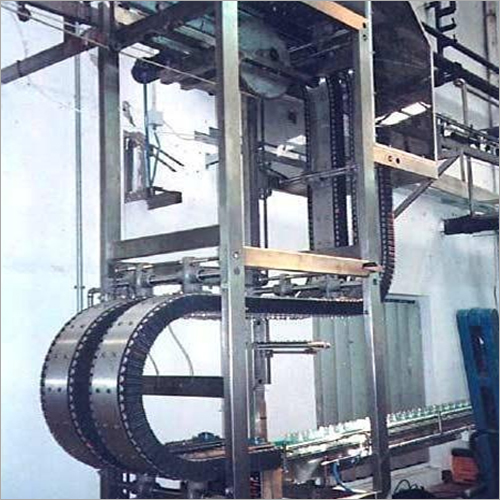

Multiflex Chain and Case Conveyor Chain Sprocket

Price 978 INR/ Meter

Multiflex Chain and Case Conveyor Chain Sprocket Specification

- Features

- High Flexibility, Low Noise Operation, Easy Installation

- Power Source

- Manual/Driven by Conveyor Motor

- Thickness

- Up to 25 mm (Depends on Model)

- Surface Finish

- Smooth, Precision Machined

- Belt Type

- Multiflex Modular Chain

- Material

- High-Grade Acetal/Engineering Plastic, Stainless Steel

- Type

- Case Conveyor Chain Sprocket

- Structure

- Modular Chain and Sprocket Assembly

- Belt Conveyor

- Not Included

- Roller Conveyor

- Compatible

- Resistant Feature

- Corrosion and Wear Resistant

- Load Capacity

- Up to 2000 kg

- Power

- Manual/Mechanical Operation

- Speed

- 1-50 m/min (depends on application)

- Usage & Applications

- Carton, Case and Bottle Conveying; Food, Beverage, Packaging Industries

- Pitch Size

- 43.5 mm, 63 mm (Standard Sizes)

- Sprocket Teeth

- 8, 10, 12, 15, Custom Available

- Operating Temperature

- -20°C to +80°C

- Mounting Type

- Keyway, Bore, or Hub Mounting

- Color

- Natural White/Black/Blue (Depends on Material)

- Compliance

- FDA Approved Materials on Request

- Packaging Type

- Boxed or Pallet for Bulk

- Chain Width

- 83 mm, 103 mm, Custom Options

- Lubrication

- Self Lubricating, Maintenance Free

Multiflex Chain and Case Conveyor Chain Sprocket Trade Information

- Minimum Order Quantity

- 200 Meter

- Supply Ability

- 200 Per Day

- Delivery Time

- 3 Days

About Multiflex Chain and Case Conveyor Chain Sprocket

Applications, Usage & Competitive Advantages

The Multiflex Chain and Case Conveyor Chain Sprocket is widely acclaimed for its adaptability in carton, case, and bottle conveyance across food, beverage, and packaging industries. Its primary competitive advantages include high flexibility, low-noise operation, minimal maintenance, and robust corrosion resistance. Easy installation and modular design make it suitable for diverse environments. Whether in automated or manual systems, this product delivers unmatched performance and longevity over conventional alternatives, garnering favorable reviews from industrial users.

Domestic Market Presence, Policy & Certifications

Catering to the premium domestic market across India, we ensure customers receive the lowest price on elite Multiflex Chain and Sprocket assemblies. Our sample policy offers easy exchanges for unmatched satisfaction before making large purchases. All products can be provided with FDA-approved certification upon request, affirming compliance and utmost safety-especially vital for food and beverage applications. Committed to excellence, we stand as a trusted manufacturer, exporter, and supplier with robust after-sales support.

FAQ's of Multiflex Chain and Case Conveyor Chain Sprocket:

Q: How is the Multiflex Chain and Case Conveyor Chain Sprocket typically used in industrial settings?

A: It is primarily used for conveying cartons, cases, and bottles in food, beverage, and packaging industries, providing smooth, reliable, and flexible transport solutions for various products.Q: What are the available options for mounting the sprocket?

A: The sprocket can be mounted using keyway, bore, or hub mounting methods, which allows easy integration into existing modular or custom conveyor systems.Q: When should FDA-approved materials be requested?

A: FDA-approved materials should be requested when the application requires direct contact with food or beverages to ensure compliance with safety and hygiene regulations.Q: Where can these sprockets be installed?

A: These sprockets are suitable for installation in automated production lines, packaging conveyors, bottling plants, and wherever modular chain systems are required, supporting both manual and mechanical operations.Q: What process ensures the longevity of this sprocket?

A: Constructed with self-lubricating and precision-machined components, the sprocket is designed to be maintenance-free and resistant to wear and corrosion, significantly increasing its operational lifespan.Q: How does the exchange policy work for samples?

A: We offer a convenient sample policy that allows customers to request exchanges on samples, ensuring complete satisfaction before committing to bulk purchases.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Modular Conveyor Chains and Component Category

Roller Conveyor Handling Component

Price 1500 INR / Meter

Minimum Order Quantity : 200

Material : Mild steel with powder coating

Thickness : Roller shell thickness: 2 mm

Load Capacity : Up to 1000 kg per meter

Type : Other, Roller Conveyor Handling Component

Contitech SilentSync Belt

Price 150 INR / Meter

Minimum Order Quantity : 200

Material : Polyurethane with Steel Reinforcement

Thickness : Varies by Belt Width and Pitch

Load Capacity : High Torque Capacity, Loading as per standard size selection

Type : Other, Synchronous Timing Belt

Table Top Chain Sprocket

Price 100 INR / Meter

Minimum Order Quantity : 200

Material : Stainless Steel / Mild Steel / Plastic (as per requirement)

Thickness : Range: 10 mm to 35 mm (customizable)

Load Capacity : High (up to 1500 kg depending on material and size)

Type : Other, Table Top Chain Sprocket

Plate Top Gripper Chain

Price 180 INR / Meter

Minimum Order Quantity : 200

Material : Stainless Steel/Engineering Plastic

Thickness : 5 mm

Load Capacity : Up to 200 kg/m

Type : Other, Top Gripper Chain

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry