Plate Top Gripper Chain

Price 180 INR/ Meter

Plate Top Gripper Chain Specification

- Power Source

- Mechanical

- Surface Finish

- Smooth Polished

- Belt Type

- Gripper Plate Chain

- Thickness

- 5 mm

- Features

- High grip strength, Durability, Easy to clean, Noise reduction

- Material

- Stainless Steel/Engineering Plastic

- Type

- Top Gripper Chain

- Structure

- Plate Top

- Belt Conveyor

- Applicable

- Roller Conveyor

- Not Compatible

- Vertical Conveyor

- Compatible

- Resistant Feature

- Corrosion and Wear Resistant

- Load Capacity

- Up to 200 kg/m

- Speed

- Up to 60 m/min

- Usage & Applications

- Inclined or Vertical Product Transfer, Packaging, Bottling, Food & Beverage Industry

- Noise Level

- Low (suitable for indoor use)

- Operating Temperature

- -10°C to 80°C

- Pad Material

- Rubber or PU for enhanced grip

- Chain Pitch

- 38.1 mm

- Color

- Standard grey / black pads

- Link Assembly

- Interlocking modular design

- Max Conveyor Width

- Up to 300 mm

- Customization

- Available for length and width

Plate Top Gripper Chain Trade Information

- Minimum Order Quantity

- 200 Meter

- Supply Ability

- 200 Per Day

- Delivery Time

- 3 Days

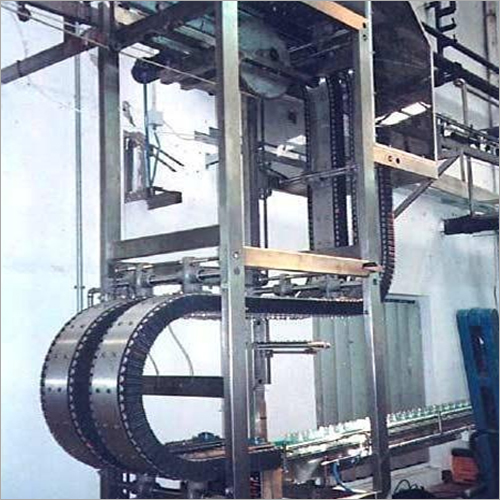

About Plate Top Gripper Chain

Our firm is recognized in dealing a wide arrangement of Plate Top Gripper Chain. It is made with a high quality of steel roller chains to increase its durability. It is highly efficient and easy to installed. It is adapted for its extreme tensile force transmission. Plate Top Gripper Chain comes in a custom made designed as per the given configurations of users. It delivers a low friction resistance which allow for direct conveyance of loading capacities.

Engineered for High-Performance Conveyance

The Plate Top Gripper Chain is specifically crafted to deliver superior product handling in vertical or inclined transport scenarios. Its robust construction and advanced grip pads ensure minimal slippage, making it ideal for delicate or high-speed applications found in packaging and bottling lines.

Adaptable to Challenging Environments

With a wide operating temperature range and corrosion-resistant materials, this gripper chain is suitable for diverse processing environments. Its smooth polished finish and easy-to-clean design support stringent hygiene requirements in food and beverage sectors without compromising durability.

Customizable and Easy to Integrate

Available with adjustable length and width, the Plate Top Gripper Chain easily integrates into existing conveyor systems. Its modular link assembly facilitates quick installation and maintenance, maximizing uptime and delivering exceptional value for distributors, manufacturers, and suppliers.

FAQs of Plate Top Gripper Chain:

Q: How does the Plate Top Gripper Chain ensure secure product transfer on inclined or vertical conveyors?

A: The chain utilizes high-grip rubber or PU pads and an interlocking modular plate top structure, which enhances product stability during inclined or vertical transportation. This design minimizes slippage and supports the safe movement of items, making it ideal for applications like packaging and bottling.Q: What customization options are available for the Plate Top Gripper Chain?

A: We offer customization for both length and width to meet specific installation requirements. Customers can tailor the conveyor chain to their unique process needs, ensuring seamless integration into various production lines or conveyor frameworks.Q: When should I choose this gripper chain over other conveyor solutions?

A: Opt for the Plate Top Gripper Chain when high grip, durability, and the ability to handle vertical or steeply inclined transfers are essential. Its suitable for industries requiring gentle yet firm handling, such as food, beverage, or packaging operations.Q: Where can the Plate Top Gripper Chain be applied most effectively?

A: It excels in environments like indoor plants requiring low noise levels, and is particularly well-suited for applications in packaging, bottling, and the food & beverage industry where hygiene, product grip, and smooth operation are priorities.Q: What process is involved in installing and maintaining this gripper chain?

A: The modular, interlocking design makes installation straightforward and efficient. Regular cleaning and basic visual inspections are generally sufficient for maintenance, thanks to its corrosion-resistant and easy-to-clean surfaces.Q: What are the main benefits of using this product in an industrial setting?

A: Key benefits include high grip strength for secure product handling, robust durability, low operational noise for indoor environments, customization flexibility, and resistance to corrosion and wear, ensuring long-term, reliable performance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Modular Conveyor Chains and Component Category

Magnetflex Curve Conveyor Component

Price 950 INR / Meter

Minimum Order Quantity : 200

Type : Other, Curve Conveyor Component

Material : Stainless Steel/Plastic

Power Source : Electric

Load Capacity : Up to 50 kg/m

Table Top Chain Sprocket

Price 100 INR / Meter

Minimum Order Quantity : 200

Type : Other, Table Top Chain Sprocket

Material : Stainless Steel / Mild Steel / Plastic (as per requirement)

Power Source : Mechanical Drive

Load Capacity : High (up to 1500 kg depending on material and size)

Multiflex Chain and Case Conveyor Chain Sprocket

Price 978 INR / Meter

Minimum Order Quantity : 200

Type : Other, Case Conveyor Chain Sprocket

Material : HighGrade Acetal/Engineering Plastic, Stainless Steel

Power Source : Manual/Driven by Conveyor Motor

Load Capacity : Up to 2000 kg

Plastic Table Top LBP Conveyor Chain

Price 500 INR / Meter

Minimum Order Quantity : 200

Type : Other, LBP (Low Back Pressure) Plastic Table Top Chain

Material : Highgrade thermoplastic/engineering plastic (e.g., Acetal, POM)

Power Source : Manual/Integrated with conveyor motor drive

Load Capacity : High; suitable for heavy loads in bottling, packaging, and material handling

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry